New DIY Electric Car Opportunities

People who have been into modified cars here in Australia have for decades known of the incredible bargains that can be had from Japanese-importing wreckers.

Because of the speed with which Japanese drivers discard near-new cars, the drivelines – or even complete front halves of cars – can be bought amazingly cheaply. Engines and gearboxes boasting late model technology, for less than the cost of having an old clunker rebuilt. It’s simple – buy a locally-delivered car and then install a new Japanese-import driveline having much greater performance. Over the years I’ve done this twice – and both times got a tremendous car for the money.

And now there’s a whole new and exciting Japanese-import field opening up.

Because Japanese manufacturers have led the world in the creation of hybrid petrol/electric cars – the first was built over 10 years ago – and because many were sold locally in Japan, hybrid car parts can now be sourced out of Japan at the same ridiculously low prices.

Don’t tell the wrecker you want a Prius electric motor. Just ask them how much a Prius ‘gearbox’ will set you back. (The two electric motor/generators in a Toyota Prius are both contained within the transmission.) Don’t say you want an Insight electric motor, say you want an Insight motor and gearbox (the motor is sandwiched between).

So what do you do with these parts?

What on paper looks the simplest project – install into another car the complete driveline from (say) a Prius – is actually the most complex. That’s because to do this successfully, you will need every part of the electric and mechanical systems – the engine, Power Split Device (ie transmission), inverter, battery, ECUs and the full wiring loom, including the high voltage cables. You’d really have to start with a complete donor car.

Better is to look at using just the ‘electric motor’ part.

I was recently at the University of Adelaide and saw how the electrical engineering department is currently installing a 50kW Prius electric motor into a Mazda (Miata) MX5.

They’ve split the Prius transmission, removing one of the electric motor/generators – and a host of gears.

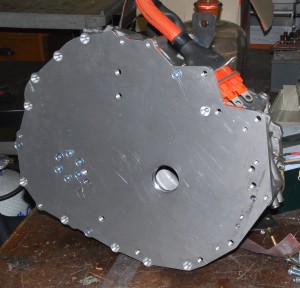

The half of the trans containing the more powerful electric motor has been retained in its totality, with the opening in the trans blanked off with a thick, machined alloy plate.

The electric motor’s output shaft has been connected to the Mazda’s gearbox by a custom-machined splined shaft, rotating through an oil seal installed in the plate.

The electric motor will be controlled by a commercial motor speed controller using custom-written software. Commercially available lithium ion batteries will be fitted.

Given that for short periods it should be easy enough to over-rate the motor’s output by a factor of three, it looks a great project – and one that I intend covering in detail when the car is on the road. (Contact Ian Linke on ilinke@eleceng.adelaide.edu.au for more details – the adaptor plate and splined shaft may become commercially available from the university.)

But is there a project that is even easier? I think so. The other day I had as a press car a Lexus RX400h. The softroader uses a complete (Prius-style) engine-and-power-split-device at the front to drive the front wheels.

But, intriguingly, at the back it has another electric motor driveline, to power just the rear wheels. This assembly combines a standalone 50kW electric motor, and (presumably) a differential. It’s also equipped with output driveshafts.

And it appears the absolutely perfect unit to install in a car as a new electric driveline.

I haven’t done the measurements but it looks like it would go straight into the front of a smallish FWD, needing only driveshaft adaptation to suit the original front hubs.

The RX400h is too recent a car to found in wrecking yards in large numbers, but rest assured, it will come.

The Prius? It’s in those Japanese wrecking yards now…

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

on January 22nd, 2009 at 9:45 am

Or one could look at finding a (wrecked) Previa/Estima Hybrid.

I had one in my workshop recently, which has a similar driveline to the RX400, with a separate electric motor in the rear axle/ diff.

Theo

on January 23rd, 2009 at 4:29 pm

just throwing this idea in the air not sure how realistic it is, but say you took a rear or mid-engine car (mr2, wolkswagen beetle are some of the cheaper examples), would it be possible to create a kind of semi-all-wheel-drive by placing one of those electric motors to power the front wheels on its own, what sort of control systems would have to be employed,and could this idea be reversed for a front wheel drive by electrically powering the rear wheels?

on January 23rd, 2009 at 4:37 pm

continuing from above

the torque available from standstill and the all-wheel drive traction would improve launching, it may have benefits in rallying circle? also is there a practical way of adapting one of these motors to be used “in-wheel” such as in the Mitsubishi Evolution IX MIEV Concept?? (link: http://www.supercars.net/cars/3233.html)

on January 23rd, 2009 at 4:39 pm

by “in wheel” i imagine they would be replace the brakes in the front…

on January 24th, 2009 at 4:31 am

I would say that the easiest way to do that would be with a FWD. The difficulties of replacing a rear suspension setup with one with driveshafts would be nothing compared to finding a compatible front suspension that is meant to have driveshafts. Remember that there are a few IRS cars with a cradle where four to six bolts holds the lot in. If the RX400h uses a cradle, putting it in a FWD car would be a comparitive snack.

I envisage a Mini Moke with a unit such as the Lexus’ electric motor. In one not so simple step you have a hybrid version of an already economical car with well over double the power (and some extra weight) of the original.

As for the control system, no real idea on how. But if used in conjunction with a normal engine/gearbox, differentiating between the need to stop accellerating and the need to change gear (both require the same inital movement of taking your foot off the throttle) would be difficult. Perhaps it’s better to start with an automatic.

If you have to have a manual, copy the control system of the manual insight, possibly with an override for pure electric mode (seeing as the electric motor is separate you can and might as well) and a *big* generator on the engine to charge the drive batteries if the car is stopped and the batteries are flat, (I think the insight can charge it’s batteries when in neutral, Julian?).

I hope that made sense…

on January 29th, 2009 at 10:26 am

If I’m not mistaken, quite a few Japanese FWD cars have been offered with a separate rear electric motor to drive the rear wheels. This is usually optional to give the car switchable 4WD to make it handle the snow better in winter, the electric motor is usually left switched off in summer, hence the car is not a true hybrid. Many of these systems are fitted to small cars such as the Cube so it shouldn’t be too hard to find one suitable for the back of a small FWD car. Add a decent sized battery pack in the bonnet of a Moke and you could turf out the old A-series in favour of electric RWD powersliding action!

on February 1st, 2009 at 12:53 am

>would it be possible to create a kind of semi-all-wheel-drive by placing one of those electric motors to power the front wheels on its own,

Anything is possible to do if you’re willing to spend the money. But if by possible you mean, “economically feasible,” then for most people it’s “No.” You’d probably need a lot of work to get an engine to work alongside an electric motor fluidly as well as braking. Also, you’d have to make sure the motor can take the RPM at high speeds without grenading.

But a bigger problem would be mounting a rear-end on the front. Where’s your steering? What about toe-in adjustment? You’d be better off with a FWD version of an AWD car and slapping it on the rear. But then, you might as well have the AWD version and dump the money into a turbo setup.

It’d be great motor idea for a Locost Seven, or other small Go Kart-esk vehicles though. Instant off-the-line torque. Come to think of it, that’d be a great idea for a high-power electric motor to eat up the low RPM powerband while a large turbo spools in a launch.

on June 17th, 2009 at 10:18 pm

Hi All, I am interested in a project and would like to ‘aquire’ the electrical components of the power train from a hybrid. Namely the motor and speed contoller. I have noted the comments about parts from Japan. Any advise?

1.. how to contact breakers who export or handle such parts.

2. looking for the lightest motor with reasonable power, say 50 kW (65 HP)

Jop, Isle of Man UK

on June 22nd, 2009 at 8:17 am

Check this out for an all Aussie conversion:

http://www.evcapri.com/

http://www.theelectriccarcompany.com.au/

on October 3rd, 2009 at 8:46 am

Hi !

The motor and diff from the back of the Lexus weighs only 31 kg.

It is oil cooled. and delivers a peak 50kw

Regards

/Per

on November 28th, 2009 at 9:59 am

Hi Per,

Thanks for the comment on the Lexus back motor trans-axle.

I have sourced one without electronics. Batteries 288V, motor 650Vac, I take it 3 phase, 9 pole, has anyone ideas about a contoller for the same, other than trying to break into the Lexus / Toyota electronic power controller??

The motor seems ideal if we can drive it.

Cheers all,

Jop

on January 19th, 2010 at 12:59 pm

Did you have any luck finding something to run the electric transaxle Jop?

on January 19th, 2010 at 7:11 pm

Hi Kris,

Re powering the trans-axle, no not yet, but live in hope.

I have sourced one, and plan to pick it up in the next couple of weeks. Investigation to proceed fron there.

Any thoughts?

Jop

on January 21st, 2010 at 12:12 pm

I’m pretty clueless Jop, just trying to get my head around what the options are. My first choice was the ACP technology but they are only talking to the corporates these days. I’ll probably end up with an AzureDynamics motor/controller combo.

I think that ex wrecker electric transaxles could be a great route for DIYs but hacking into the original hybrid controller or adapting an existing FVD to run one are both beyond me.

What we need is a tame ElegEng undergrad to do the heavy lifting for us with a design?

on January 21st, 2010 at 6:48 pm

Hi Kris,

Yes you are right. WHen / if I get the parts, that is the route we will be going. Looking at the original controller. Can we make it run one motor? I will say don’t expect quick answers from us.

Ours will be a gentle (euphmism for slow) investigation.

We have set new delayed targets for the ac drive.

We will be running our dc drive for the time being.

Jop

on January 26th, 2010 at 9:20 pm

[…] 2) New DIY Electric Car Opportunities […]