Automobile Factory of Despair

I’ve just read a fascinating and powerful book.

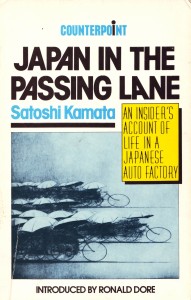

Japan in the Passing Lane was written in the early 1970s by Satoshi Kamata, a Japanese freelance journalist. The English translation was published in 1983. Kamata’s preferred title – Automobile Factory of Despair – is perhaps a better description of the book’s contents.

Kamata joined Toyota as a seasonal worker, one employed for a 6 month period. In the book he describes by means of a daily diary what life in a Toyota plant was then like. The job was harrowing, exploitative, mind-numbing, dangerous – and enormously hard work.

The assembly line moves so fast that Kamata, working in a plant making gearboxes, can barely keep up. That might be understandable when he was first introduced to the job, but it also remains the case months later.

He describes the tasks he has to do at his station:

1. I pick up two knock pins (small pieces of steel shaft) with my left hand from a parts box (where identical parts are stored) in front of the assembly line. I insert them into the upper holes on a gear box and then knock them in with the hammer in my right hand.

2. With my right hand, I take an input shaft out of a tin box coming down the assembly line. I insert it into the center hole of the gear box. Holding the input shaft from the other side with my left hand, I drive it in with the hammer. (Sometimes it doesn’t go in easily.)

3. With my left hand, I screw a synchronizing ring to an end into which an input shaft has been driven.

4. I turn the gear box around.

5. With my left hand, I take out a reverse idler gear from the tin box. I put it into the gear box and press it with my hand. With my right hand I take a shaft out of the parts box and insert it into a hole on the opposite side of the gear box. I insert the shaft through the idler hole and then fit it into the gear box. With my right hand I pick up a small semicircular pin (it’s hard with gloves on) and force it into a slot on the shaft to connect it to the gear box. (The pointed end of the shaft doesn’t always go smoothly into the hole in the gear box.)

6. The line brings an output shaft (which has many gears) placed upright in a hole in the gear box. I lift it with both hands and place it horizontally into the gear box. Then I connect it to the input shaft that I put in previously and fix them in their correct position in a slot so that they rotate freely.

7. With my left hand I reach over to a box on the other side of the line to get a molded metal fork. With my right hand I take a hub out of the tin box. I connect the parts at two places, using two clips that I’ve picked up with my right hand (very difficult with gloves on!).

8. With my left hand I pick up a bearing lock from the tin box. Then I turn around. I place the bear¬ing lock on top of a line mount. I pick up a rubber oil seal and put it into a hole in the bearing lock. Pressing the oil seal with a cold-chisel-shaped stick in my left hand, I hammer the oil seal in. (If I bend the oil seal, the transmission will leak oil.)

9. After hammering the oil seal in, I take out a paper gasket that’s hanging down in front of my eyes. I soak it in liquid bond and then apply it to the rim of the bearing lock.

10. I turn around again and face the line and put the bearing lock on it. I grab the hammer and start doing step 1 again. In all, I assemble fifteen big and small parts.

And what time is given to complete these tasks? – 78 seconds! Over the course of one shift, more than 300 gearboxes are made – a number that increases as the book progresses and the line is speeded up still further.

Kamata, who lives in the company bachelor barracks (like many seasonal workers, he’s left his wife at home in a distant town), works for up to 5 hours without a break, is required to do overtime hours resulting in 10 hour days, sees people being injured (eg losing fingers) and then being effectively blamed for their accidents, watches as his own and colleagues’ health break down – and sees production, production, production being pushed at all costs.

He also writes about a company culture that employs large numbers of ex Japanese Self Defence Force personnel in security and control roles, that posthumously promotes workers killed in plant accidents (a cap is placed on the coffin, its markings indicating the dead man is now one rank higher), and that houses and controls its workers in an environment much more akin to a prison than anything else. He sees the workers’ union as a complete captive of management.

You might conclude that Kamata is an embittered Marxist, an ideologue driven by class warfare to write a biased account. But the diary reads very differently to that: this is a man who simply reports on what he can see. Writing his diary each night before he falls on his bed in an exhausted sleep, he is almost understated and divorced in his descriptions.

Today Toyota is the largest manufacturer of cars in the world. It’s also the richest car company and in some respects the most technically progressive.

But I’ll never forget Satoshi Kamata’s descriptions of how in part that was achieved…

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

on April 23rd, 2008 at 11:36 pm

RE Automobile Factory of Despair

Seems like we all snap up a well priced product with little concern for humanity – just look around the house at the stuff we have bought that is probably made in conditions like those described ,or worse.

While Dick Smith and the Buy Australian sentiment lasted a while, I must confess to buying some cheap products without much thought about child labour, gross health and safety breaches and uncontrolled pollution of the environment. Now we are to get cars imported from China, while the Free Trade Lobby advocates another reduction in tarrifs!!

Ford and GMH might as well shut up shop now and move to full import status like every other manafacturer has done before them. As it is, Australian cars now contain evermore major components which are imported. The L6 Ford engine is the last locally made engine, all manual and now most auto transmissions are imported. Trying to manafacture anything here, while maintaining fair wages and descent OHS and minimizing pollution now seems impossible, especially without the economies of scale which Third World plants can benefit from.

I guess we will just keep digging stuff out of the ground, putting it into leaky “Flag of Convenience” ships and bringing in cars etc as backload. What hope is there for the Falcon and Commodore or the Aussie built Fiesta which is coming?

on August 19th, 2010 at 6:14 am

Thanks for the review, after just having finished “The Toyota Way” I am more then eager to read this book.