Chassis Design

Imagine you were living in the late 1930s (and of course, a very small number of you may well have been!). Then, as now, cars had four wheels, a body, engine, suspension and brakes. But they often had something else as well – a chassis.

Nowadays, nearly all cars use monocoque construction, where the pressed steel body provides the required stiffness. The main exceptions are traditional off-road four-wheel drives and trucks and buses – these vehicles still largely use a separate chassis. A few bespoke cars also use non-monocoque construction; for example, a tubular space frame.

But even in the late 1930s, you could have seen plenty more designs that just a traditional chassis. Have a look at these – all are taken from The Mechanism of the Car, written by Arthur W Judge and published in 1939.

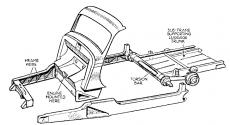

Firstly, we have monocoque (or unitary) construction. This Vauxhall retains a separate bolt-on chassis for the front suspension and engine mounts, an approach common in cars up to the 1970s.

Firstly, we have monocoque (or unitary) construction. This Vauxhall retains a separate bolt-on chassis for the front suspension and engine mounts, an approach common in cars up to the 1970s.

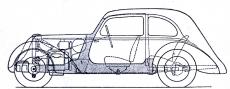

But then we have the cast aluminium frame. What?! Yes, a car being sold in 1939 (the Hotchkiss Amilcar) used a frame formed from cast aluminium members bolted together.

But then we have the cast aluminium frame. What?! Yes, a car being sold in 1939 (the Hotchkiss Amilcar) used a frame formed from cast aluminium members bolted together.

Here’s how the cast alloy frame integrated itself into the car.

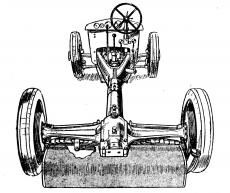

Then there was the tubular frame, as used by Austro-Daimler. The very large diameter central tube would have given both high bending strength and also resisted torsion.

Then there was the tubular frame, as used by Austro-Daimler. The very large diameter central tube would have given both high bending strength and also resisted torsion.

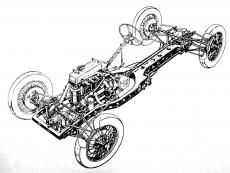

And finally, we have a car that’s absolutely intriguing – and one I’d never heard of before. It’s simply listed as the ‘MG Racing Car’ and uses a backbone chassis formed from pressed, welded plate. The car also features double wishbone suspension front and rear – perhaps the first car to ever do so.

I think that these drawings are worth looking at closely (you can click on them to enlarge). In mechanical car design, there’s very little new under the sun…

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

on April 10th, 2008 at 10:11 pm

Is it still legal to pop rivet a chassis together & would it still need to be x-rayed