When wheels steer themselves

I thought that the idea that car wheels just went up and down over bumps, and were steered only when the driver turned the steering wheel, was pretty passé.

Passive ‘steer’ systems have been in production cars for many years, normally of the rear end.

In broad brush strokes, the systems work like this: The rear bushes are set with differing stiffnesses in different planes, such that when the wheel is subjected to a lateral force (as it is in cornering), it no longer remains parallel with the car’s long axis – that is, it steers.

For example, rear wheel compliance steer is often set to give toe-in, thus settling the cornering car.

The original Mazda MX5 / Miata had such a system. (It’s worth pointing out that the MX5 is generally regarded as one of the best handling, relatively cheap, cars ever released.) In their 1989 book MX-5 – the rebirth of the sports car in the new Mazda MX5, Jack Yamaguchi and Jonathon Thompson write:

No Mazda rear suspension is complete without some form of self-correcting geometry, as have been seen in the fwd 323 and 626’s TTL (Twin Trapezoidal Links), the 929’s E-links and the RX-7’s complex DTSS. The MX-5 double wishbones are no exception, though to a lesser degree. The designers need not worry about camber changes; a recognized virtue of the unequal length A-arm suspension is the admirable ability to maintain the tires’ contact area true to the road surface, attaining a near-zero camber change.

So the chassis designers’ efforts were directed at obtaining a desired amount of toe-in attitude that improves vehicle stability in such maneuvers as spirited cornering and rapid lane changes. Toe-in was to be introduced when the suspension is subjected to lateral force, not to accelerative or braking force. They considered that the MX-5 with its configuration, weight and suspension, would have sound basic handling characteristics, and the lateral reaction would be all it would require to further enhance its vehicle dynamics.

The lower H arm’s wheel-side pivots, which carry the suspension upright, have rubber bushings of different elasticity rates. The rear pivot is on a firmer rubber bushing than the front. The front rubber bushing deforms more under load induced by lateral force, and introduces an appropriate amount of wheel toe-in, which is in the final production tune a fraction of a degree.

Pretty well all current front-wheel drive cars have some form of passive rear wheel steering. The Honda Jazz uses a tricky torsion beam rear axle in which, according to Honda, “the amount of roll steer and roll camber has been optimised to deliver steady handling”.

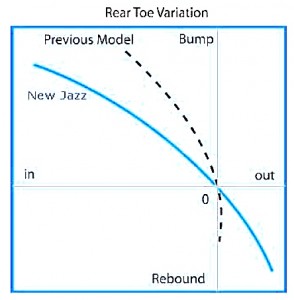

But even better, the company has released graphs showing the toe variation over suspension travel (note: travel, rather than lateral force), with the current model compared with the previous design. As can be clearly seen, in bump (as would occur to the outer wheel when cornering) the Jazz (especially the new model) has an increasing amount of toe-in. Also note the differing shape of the curves in rebound (droop).

And it’s not just the ostensibly non-steered end that uses toe variations built into the suspension design.

Several suspension textbooks that I have suggest that setting up the front, steering wheels for non-zero bump steer can be advantageous. Chassis Engineering by Herb Adams (incidentally, a very simple book much under-rated) states:

Exactly how much bump steer you need on your car is like most suspension settings—a compromise. It is common to set the bump steer so that the front wheels toe-out on a bump. This will make the car feel more stable, because the car will not turn any more than the driver asks.

To understand this effect, picture what would happen if your car had toe-in on bump. As the driver would start a turn, he would feed in a certain amount of steering angle. As the car built up g-forces, the chassis would roll and the outside suspension would compress in the bump direction. If the car had toe-in on bump, the front wheels would start to turn more than the driver asked and his turn radius would get tighter. This would require the driver to make a correction and upset the car’s smooth approach into the turn. The outside tire is considered in this analysis because it carries most of the weight in a turn.

Assuming that your car has the bump steer set so that there is toe-out in the bump direction, the next consideration is how much toe-out. If the car has too much toe-out in bump, the steering can become imprecise, because the suspension will tend to negate what the driver is doing with the steering wheel. Also, if there is too much bump steer, the car will dart around going down the straightaway. A reasonable amount of bump steer would be in the range of .010 to .020 per inch of suspension travel.

Fundamentals of Vehicle Dynamics by Thomas D Gillespie positively describes using roll steer, where the toe variation of the left-hand and right-hand wheel is in the same direction, to alter understeer and oversteer effects.

Even that most exotic of road cars, the McLaren F1, had designed-in passive steer.

Writing in an engineering paper released in 1993, SJ Randle wrote of the front suspension: “Lateral force steer…. was 0.15 degrees/g toe out under a load pushing the contact patch in towards the vehicle centreline. This is a mild understeer characteristic – precisely what we wanted.”

In the case of the rear suspension, “the net result being a mild oversteer characteristic (ie toe out under a force towards the car’s centreline) or around 0.2 degrees/g. We had hoped for an understeer of 0.1 degrees/g.”

Such passive steer suspension behaviour would become especially important in vehicles that, in order to achieve other design aims, have dynamic deficiencies. So for example, a very light car that is aerodynamically neutral in lift, and has a low aero drag, is likely to be susceptible to cross-winds. On bump the passive toe-in of the rear wheels, and toe-out of the front wheels, would help correct this yaw.

Note that adopting these techniques doesn’t require the actual mechanical complexity – or weight – of the suspension systems to change.

But of course it’s quite possible to over-do these effects. As indicated in the quotes above, we’re talking very small steer angle changes. You can’t even transfer the ideas from car to car: the current Honda Jazz steers fine; the Honda City (that apparently uses the Jazz rear suspension) has an unmistakeable, unhappy, ‘rear steer’ feel that is disconcerting on quick lane changes.

But it seems to me that if you are building any bespoke vehicle and simply state point-blank that there should be no bump steer at the front, and no lateral compliance leading to toe changes at the back, you’re taking away a pretty important string from your bow.

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

on April 2nd, 2009 at 4:02 am

If I am following all of this right Julian, then potential car modifiers beware, changing certain bushes to polyurethane bits can dramatically alter a cars handling negatively due to lack of compliance. yes?

on April 2nd, 2009 at 5:53 am

Yet another reason (besides the noise and constant need for grease) why I wish people would quit throwing hard urethane suspension bushings on their cars in the effort to improve handling. Of course the handling improves post bushing install, the ones that were removed were fifteen years old! What needs to be considered is how few suspension arms move in a single plane and how much compliance was engineered into the original bushings in order to achieve the characteristics you are discussing. People, please, just install new OEM bushings first. If the car was suitably performance oriented from the start you’ll be hard pressed to outsmart the whole team of suspension engineers and test drivers who developed the stock bushings.

on April 2nd, 2009 at 12:44 pm

My Peugeot 205 GTI has solid blocks of metal with studs holding the rear torsion bar subframe to the bodyshell where it originally had rubber bushes.

The mounts I have fitted were available from the Peugeot factory (Peugeot Talbot Sport – PTS) back in the day as Group A mounts. There was also a Group N mount which was a much firmer version of the standard rubber mount, this still has a passive steering effect but only a fraction of the original setup. I’ve tried them all on lots of different 205s on road and track and I definitely prefer solidly mounted suspension in every case so far. Lift off oversteer is much more controllable with the beam solidly mounted compared to OE bushes, especially aged OE bushes when the handling can get quite dangerous surprisingly rapidly. It was normal to find the rubber completely separated from the metal plates they are mounted to on 205s with more than about 75k miles on the clock and the handling would have been gradually deteriorating in the leadup to them splitting over a long period of time but obviously a solid mount will have consistent handling indefinitely.

These links show some modern reproductions of the old factory group N/A mounts:

http://www.bakerbm.com/205.php?data=suskit205n

http://www.bakerbm.com/205.php?data=suskit205a

on April 3rd, 2009 at 8:53 pm

Jack

Since these bushes seem to connect the whole rear subframe to the body I guess they won’t affect roll steer of an individual wheel – but will reduce the force induced steering of the whole rear end? Is this applicable to old Peugeot 206’s – I imagine they might have a similiar bushing setup etc?

on April 5th, 2009 at 8:06 am

Thats correct, however the inside rear wheel is very lightly loaded so its largely irrelevant IMO, during hard cornering it will often actually leave the ground entirely.

I wouldn’t be surprised if a similar device is available for the 206, they have a similar rear suspension design. They certainly are for the 306/Citroen ZX/Xsara.

on April 16th, 2009 at 2:10 pm

Roy, for the same argument, tyres have improved in those 15 years as well so the deflection of the tread is minimized in comparison. Sure if you used the same tyres and wheels from OEM then change nothing. I currently use run-flat tyres with much increased sidewall strength on the street, and I use semi slick tyres on the track with phenomenal grip and sidewall strength so naturally I have increased durometer bushes (only because rose joints are too harsh for a road car) and have adjusted the camber accordingly. Certainly added maintenance is necessary, but that is part of owning a vehicle with more than twice the factory power output. Unfortunately too many uneducated modifiers carry out changes for bragging rights, without understanding the maintenance requirements and there is little we can do about that.

on August 21st, 2009 at 3:15 am

Ahhh, those McLaren F1’s are soooo sweet!

on August 22nd, 2009 at 4:26 am

I had been told to go the urethane route, but Roy you do have a point. I don’t think I’m smarter than the suspension engineers, and a new set of stock bushings is probably just as good (or better) than urethane. I’m intrigued by the idea of self steering though. I might have to check out a MX5.