I am not a natural designer; never have been and never will be.

The designs I produce are therefore the work of many hours of tortuous thought: of sketching and thinking; of looking up reference books and thinking some more.

Even a simple bracket can take me a long time; a more complex system can take me so many hours that, to be honest, you’d be frankly disbelieving if I told you the total.

How I envy those who combine natural artistry with engineering skills; those who have the ability to create beautifully elegant structures and shapes that also perform with engineering integrity. I think of those attributes – and the people who spring to mind are designers of bridges, of buildings and of dams: civil engineers and architects, rather than mechanical engineers.

Isambard Brunel and Thomas Bouch, certainly.

In the automotive field, it is hard to think off-hand of revered designers who could combine artistry with engineering elegance.

Colin Chapman?

Perhaps.

Ferdinand Porsche?

More so, I think – but ‘Porsche’ normally also includes son Ferry… so perhaps you’re getting two for the price of one.

Gordon Murray?

Yes, probably so.

Alex Issigonis?

Engineering? Without a doubt! Aesthetics? He had no bloody idea.

Anyway, as I was saying, automotive designers tend not to be able to combine innovative ideas with artistry.

Me? I can’t do innovation or aesthetics!

But I can try.

One of the outlets for my attempts has become, over the last few years, human-powered vehicles. Pedal bikes and trikes, if you like.

(A few years ago I had steel coil springs custom-wound for the suspension of a recumbent pedal trike I’d designed.

When I contacted the spring company – and in following discussion – I called the vehicle a ‘human-powered vehicle’.

When I picked up the springs, the salesman loudly proclaimed: “So these are for the bike, are they?”, by emphasis and with a touch of derision, clearly making his thoughts felt.

I replied: “Well, it’s got three wheels, so that makes it a trike doesn’t it?”

With visions of a child’s tricycle filling his mind, he was speechless.)

One of the beauties of building an HPV is that you can try pretty well anything you want – both legally and physically.

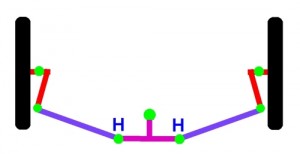

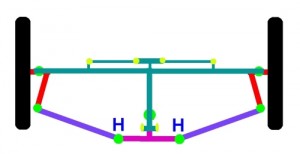

In my first really successful HPV, I used a front suspension design comprising semi-leading arms, with an anti-roll bar and a high geometric roll centre. Damping was by track change and Firestone rolling lip airbag springs were the springing medium.

(And if you think: “Yeah, whatever – WTF… that’s how I was too a few years ago. Boy, does building our own vehicle make you think hard about fundamental concepts of vehicular design!)

With its massively high roll centre and changing track, varying castor and camber, this suspension design went against almost everything I have ever read about suspension (for any vehicles!) – but on-road, it proved to be very good indeed.

And to be quite honest, that makes me feel warm inside: I did something that, AFAIK, no-one else has done on a vehicle – and it worked!

(Of course, someone, somewhere must have done it – but it’s certainly not a recognised front suspension design.)

Today, I got to the stage in my latest HPV build that I could statically assess the new front suspension – in terms of travel and roll stiffness, at least. (As I write this, the machine is at least another week away from road testing.)

And, at this early point in the design, it looks really good.

How so?

Well, it resists dive more than a single wheel bump. In fact, it has a much lower spring rate for a single wheel bump than a two-wheel bump. And, since most bumps are one-wheel, that’s good.

It incorporates the function of anti-roll bar into a suspension member. That saves potentially a lot of weight – not just for the anti-roll bar, but also for the links and rod-ends and anti-roll bar bearings.

And the suspension design has only four ball bearings (at a total of two pivot points).

…and it weighs – including suspension arms, pivot point bearings and two springs – just 1.4kg.

To carry a max dynamic load of about 150kg.

Its design? It’s a leading arm, torsion tube, dead axle, with a Watts link.

Weird? Very!

Unheard of? Again, I am not aware of any vehicle of any description using this approach on the front, steering, suspension.

Effective? I’ll find out when plunging down my local 20 per cent grades at 60 or 70 or 80 km/h, clad only in shorts, shoes, a t-shirt and bike helmet…

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.