Having an electrical problem

I did an automotive electronic installation the other day. It’s a particular job I have done many times before – installing driving lights on a vehicle – but I came across a problem I’ve never before experienced.

After bolting a pair of Narva 175 driving lights onto the front of my wife’s Skoda Roomster, I decided to buy another pair for my own car. Simply, considering the cost of the Narvas, I was very impressed with the quality of the illumination upgrade on the Skoda. In addition to a relay, switch and terminals, the Narva package contains both wide and narrow beam lights; I found the effective combination of spread and penetration makes a huge difference to night-time driving safety.

And not just safety – I’ve done a few long distance drives in the Narva-equipped Skoda and it’s a lot les fatiguing driving with good lights.

On my Honda the installation was always going to be relatively difficult. As with many cars, the Insight has no real mounting spots for additional lights. The approach taken by many – install an adaptor held in place with the number plate screws – didn’t do a lot for me so I searched on the car for places where brackets could be mounted. In the end I welded together a square tube assembly that sits just in front of the radiator but behind the bumper, held in place with welded-in spacers and bolts that pass through original sheet metal holes. The lights themselves mount on 10mm threaded rod through thick flat steel brackets brazed to the square cross-tube.

I also took some pains with the wiring, choosing not to use the relatively thin wire provided with the kit. Instead I ran thick, dual-core cable from each of the lights back to the Narva-supplied relay that I mounted on a new bracket located close to the battery. I added a 20 amp blade fuse in a holder and triggered the relay from the high beam headlights.

Being a slow worker and taking my time, it took about a full day.

That night, I went out to aim the lights. Driving around the country town in which I live there are plenty of dark streets and country roads to use – things were going smoothly until I suddenly found a major problem. After the driving lights had been switched on for a few minutes, they wouldn’t turn off! I had to actually pull over, lift the bonnet and physically tap the relay to get the lights to extinguish.

That made me unpopular with oncoming traffic and so after this had occurred a few times I gave it up and went home.

The next day I measured the voltage across the relay’s coil’s contacts. Relays disengage at a much lower voltage than they pull-in (for example, a 12V nominal relay might not disengage until the voltage has dropped to 3V) and I wondered if there was a residual voltage keeping the relay engaged. However, a check showed that while there was a voltage on the wire (even with the high beams off), it amounted to only 0.3V – and any 12V relay should be turned off at only 0.3V!

So what was going on? I swapped the Narva relay for another relay I had in my spare parts drawer and the new relay operated without any sticking problems. So the original relay was the issue.

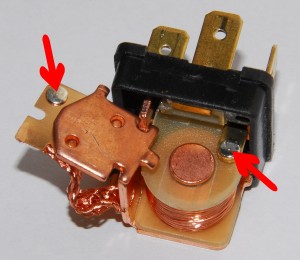

I then pulled open the Narva relay to find that, on the contacts, there was a tiny but obvious burn mark (arrowed). The relay contacts, despite being quite large in area (as befits a 30 amp relay) were in fact touching at only a tiny spot. The contacts were literally welding themselves together!

That’s pretty weak in a brand-name driving light kit. So while I still admire the light output, I think if I fit any more of these lights, I might supply my own relay…

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.