Hi Liam,

Thanks for your questions. I hope my answers help you in your Year 11 design and technology studies.

Is designing a hobby, a source of income, or both?

My designing is both a source of income and a hobby. I enjoy doing what I do: if I can make it both my work and a hobby, so much the better.

Initially, I started out doing things just as a hobby, but then I realised that by simply describing (in pics and text) what I had done, and selling it as a magazine article, it could pay me money as well.

How long have you been designing things for?

I think I probably have been designing real things since I was about your age. In Year 11 I got an electric drill and then an electric jigsaw, and started building speakers systems and solar heaters. My designs were thought-through, and then sketched on paper, before I started building. So they were projects that were designed – not just built as I went along.

I can remember designing things earlier than that – say, in Year 8 – but I never then actually made them, so I don’t think that counts.

Which part of design gives you the most satisfaction?

That’s a really good question – one that I have not thought of before.

I think perhaps the thing that gives me the greatest satisfaction is designing and building something that lots of people say will not work, or is stupid, or is a waste of time – then finding that it works really well.

When I designed and built my first suspension trikes, everyone who knew anything about recumbent trikes said things like: “Why would you bother – trikes without suspension ride fine.” Now, about ten years later, I see plenty of mainstream trike blogs and sites reviewing commercial suspension trikes and saying how great they are!

It’s both frustrating and rewarding – frustrating when I come up with something I think is great, and then (eventually) rewarding when people recognise years later that what I said was great, was in fact great!

What kind of projects do you most enjoy working on?

I think I most enjoy projects that involve vehicles – things you can pedal or drive on the road. I reckon that being in control of a moving thing that you designed and built (or even just modified) is the very best.

I also have designed and built electronic projects, pneumatic projects, speaker systems, solar heaters – and many other things… but I reckon that vehicles beat them all by a lot.

What has you favourite design project been so far? And why?

My favourite project is usually the thing I am currently working on.

So today I designed and started to build a trailer for my tractor lawnmower. It uses pillow-block bearings for the axle, hubs I machined on a lathe, and a 25mm RHS square tube frame, MIG welded together.

I have to do my “real” job tomorrow, but later in the week I want to finish the trailer, installing a steel deck and hardwood side rails.

I am also currently working on turbocharging my hybrid Honda Insight, and it’s been fun coming up with a water/air intercooler and new airbox for the car. I also made my own machine to place a lip on the intercooler tubes, to stop the turbo boost hoses blowing off under boost.

But this time last year, I was all excited about designing and building twin 15-inch subwoofers to put under the floor of my lounge room!

It’s good to be excited about whatever you are designing and building.

What’s the process you go through during a design project?

Here are my steps:

1. What functionality does the design need to have – what does it have to do?

2. What have other people done to address the same needs?

3. What aspects of their designs can I use, and what aspects can I develop that will better suit my needs and building capabilities?

4. What aspects from similar designs, but in completely different design areas, can I use? (So for example, when designing a stiff but light structure – what aspects from aircraft, from yachts, from airships, from skateboards, from bicycles, from rockets can I incorporate in my project?)

5. Can I build my design with my skills, money and workshop equipment? If not, how can I change it?

6. Now it’s time for sketches – lots of them.

7. Build the thing.

What’s the process you go through when building it?

1. Follow sketches

2. Any design changes that I decide to implement during the build, I re-sketch and then consider very carefully before doing.

On average how long will a design project take? From the initial concept to a finished design.

A really big project, like my three recumbent suspension trikes, perhaps 9 months to a year for each of them. My turbocharging (and intercooling, and fitting programmable engine management, and fitting a MoTeC dash, and full tuning, and tweaking the electric control system, and fitting a new HV battery pack) to my Honda Insight I’d expect to take 9 – 12 months.

I am a slow worker and will make a part again if I am not happy with the first version.

What are your preferences or priorities in terms of things like: form, function, durability and build-ability?

Form: I don’t consider aesthetics (how pretty it looks) much at all. Good design has an elegance and beauty of its own.

Function: is critical – it must perform.

Durability: in the sort of things I design and build, I look at durability in two key areas. These are high quality bearing surfaces (eg use of ball bearings), and fatigue strength (over-engineering to stop fatigue failures).

Build-ability – very important – I have to be able to build the thing (or use others only very sparingly).

When starting a design project do you prefer to start with a clean sheet or start from what others have done?

I like starting with a clean sheet and only then looking at what others have done. Sometimes I learn a huge amount by looking at others have done – other times, I think my ideas are better.

But always consider first what you want to do and only then look at what others have done.

Do you use computer modelling when working on a design project?

The only computer modelling I use is in the design of subwoofers – I don’t use any other computer aided design at all. This is mostly because I am very old, but also because I seem to better develop my ideas by:

1. Sketching – drawing ideas as I am thinking them up.

2. Making small models – that show (through destruction testing) how strong they are, where any moving parts will hit each other, etc.

3. Making rough versions and seeing how good they are before building the proper one. That’s especially the case in electronic and pneumatic systems.

I think if I were starting now I would be particularly interested in getting good skills in CFD (computational fluid dynamics – how fluids like air pass over objects), and CAD – computer aided design, especially in the stressing of parts.

What have you found to be the critical elements in the design of a HPV to meet your particular goals/needs?

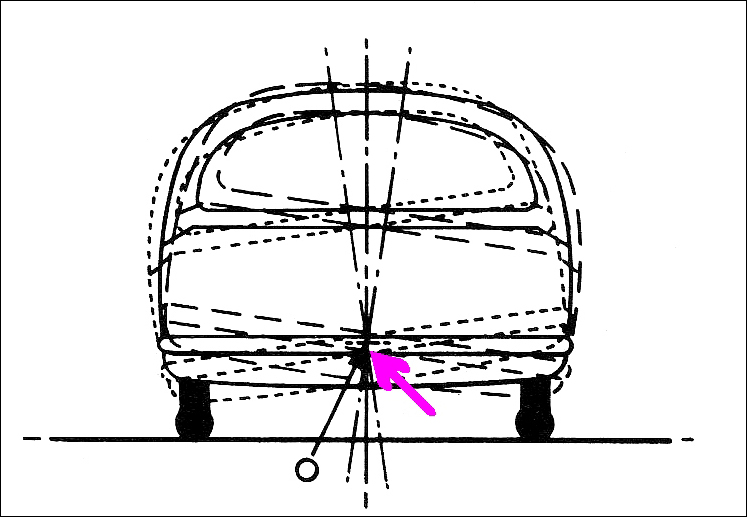

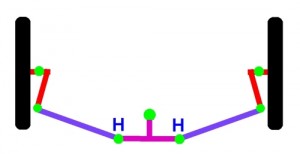

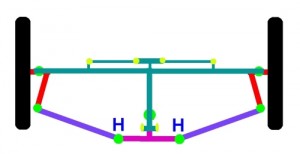

One critical element in designing a suspension HPV (Human Powered Vehicle) is to use the lightest approach to achieving the outcome that you want – and you should be striving for an outcome where the suspension natural frequency is about 1Hz (for an explanation, see http://www.autospeed.com/cms/article.html?&A=112279).

If the suspension is sufficiently soft to absorb bumps, you then need very effective anti-roll capabilities to stop excessive body roll on corners.

Another critical element is to optimise steering – this is because the rider gets most of their handling feedback through the steering response and behaviour. Optimising this includes Ackermann, caster and trail.

But to make it all really simple – the HPV should always behave as the rider expects. Actually achieving that is incredibly difficult.

How do you decide when a design is finished e.g. is the HPV project finished or just on the back burner until you can implement another set of ideas?

I finish one HPV project and start another when I think that starting from scratch is a better way of pursuing the next set of ideas.

To finish, do you commercialise you designs in any other way than publishing them in articles?

i.e.

o Protect any intellectual property you develop?

o Keep secret particular problems or solutions you have found?

o Look at production of your design?

I have looked at doing all those things and have decided that it’s best for me if I just write (and photograph) my designs and run them in paying publications. I also always tell it like it really is – not trying to hide any problems or solutions.

Commercialising a new design requires lots of risk in terms of money, and the further ahead of the other competitors that the design is, the harder it is to get it accepted.

Regards,

Julian Edgar

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.