Heading down a blind alley

Right now my confidence is at an utterly low ebb.

I have been working on my new recumbent, touring bike design and now, after almost two months of thinking, designing and constructing, have abandoned the project in its current form.

The machine has several strict criteria it must fulfil: it needs to be able to be folded into a package (say) 1 metre x 50 cm x 40 cm; it needs to be able to carry a lot of camping gear; it needs to be stable; and it needs to weigh less than 20kg. Oh yes, and as I have previously indicated, it needs to use a recumbent seat and have a lot of gears.

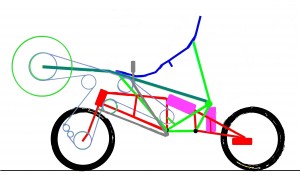

My first on-screen design looked a bit like this. A delta trike, it used (two and then) three air springs, allowing interconnection of the front and rear suspensions. The machine used chain-twisting front-wheel drive and rear wheels that could lean, parallelogram-style. The leaning ability could also be locked out for low speed travel.

But then I realised that the integration of a ‘lean lock’ with the rear suspension design wouldn’t work: when lean was locked-out, the rear suspension would cause the trike to tilt badly when one rear wheel ran over a bump.

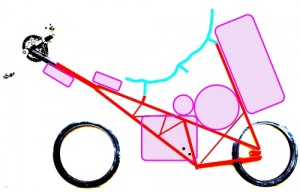

So the interconnected suspensions disappeared – this became the next design (the massive carrying capacity is obvious).

I spent weeks building this machine before I realised that the problems were becoming insurmountable.

What problems then?

Well, firstly the machine has to suit my wife as well as me, and for her the seat height was too great. Yes, she could just get on and off, but not really comfortably.

Then I found the steering very difficult to organise – I could get rid of the bump steer, but only with an overley complex steering linkage.

To accommodate the chain, the front forks needed to be an odd shaped, weaker, design. And, after setting the system up, I wasn’t all that happy with the FWD twist-chain approach anyway.

Weight was growing, too – there was no way it would come in under 20kg.

As I came across problems and then adopted fixes, the build was becoming one band-aid after another. As a result, the integration of the design was getting poorer and poorer.

Then the tall centre of gravity height meant that rear track needed to be wider than expected to provide sufficient stability.

It may be possible to use a ‘tilt brake’ together with 150mm of suspension travel – but I couldn’t work out how to integrate the two ideas. Not while still keeping the suspension working in all situations, and avoiding excessive suspension-induced body roll in ‘locked’ form.

And finally: the design was simply getting too complex for a machine that has to be reliable and bullet-proof.

Part way through a project, it takes a real mental effort to step back and say: “Nope, this isn’t going where I want it to go.”

That’s partly because that voice inside your head keeps saying: “Failure, failure!”

It’s also because you look at the time and money already spent – the design had already consumed something like $500 worth of high tensile 4130 steel tube and sheet. And I hate to think how many hours of thought and construction.

So right now I am thinking afresh. Simple, (relatively) light, easy to build.

Of course it hasn’t all been a complete waste of time – I know a lot more about the achievability of certain design criteria, and my skill at brazing has been refreshed.

But still, it certainly knocks the confidence out of you…

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

on February 12th, 2009 at 8:11 am

“Of course it hasn’t all been a complete waste of time – I know a lot more about the achievability of certain design criteria, and my skill at brazing has been refreshed.”

You’ve contradicted yourself, Julian. You’ve learnt important lessons and practiced your skills, but you wasted time……

That dirty little failure voice that is bread into us starts very young. You’re not failure if you take away useful lessons, no matter how big the mistake(s).

Sorry to say it, but you realy did sound like a typical school teacher. “You made a mistake, you failed.”

on February 12th, 2009 at 8:22 am

You’ve contradicted yourself, Julian.

No I didn’t. I said it had not been a COMPLETE waste of time. It certainly was a partial waste of time.

I don’t like failure.

If that makes me sound like an ex school teacher, so be it.

on February 12th, 2009 at 1:53 pm

How strict is the “folded” requirement. What if instead it broke down to a few components held together with split pin and/or quick release type mechanisms?

Surely that’d give you some more flexibility in design, perhaps a longer and lower bike for stability, but still pack away to 100x50x40 albeit with a longer setup and breakdown time.

on February 12th, 2009 at 2:09 pm

It was never going to be fully folding – seat would have unbolted. I definitely won’t be able to get into the 100 x 50 x 40 envelope – maybe now 90 x 70 x 50

on February 12th, 2009 at 2:29 pm

Also, have you tried looking to the Carver One for some inspiration? Obviously you’d need some sort of leaning mechanism without the electronics.

Perhaps some sort of leaning body and front wheel with an oversized skateboard truck arrangement at the rear (getting the desired travel might prove difficult).

on February 13th, 2009 at 12:58 pm

I do hope we are going to see photos and details of the “failure”.

I know this will be hard to do. But I think we learn more from a good-attempt-failure than we do even from a success. Sure a no-clue failure is worth little more than amusement value, but a good try has all sorts of lessons.

on February 13th, 2009 at 1:06 pm

I sometimes present failures when I think there’s plenty for others to learn from and it will be of widespread interest eg Honda Insight undertray, peltier cooler intercooler waterspray

But I won’t be doing any more in this case – HPVs are not mainstream AutoSpeed and I will be covering the final Chalky in a dedicated series, so that will be sufficient content on the topic for a while.

on February 14th, 2009 at 7:56 am

Off the topic, but you did mention the peltier spray.

Did you think of using the large body of water as the hot side (or heat dump, whatever you wish to call it)? This way you only need to cool the water you use, but the down-side is that the water slowly heats up. Not an issue for short spurts, as you would probably have used nearly half the water before the temperature of the water at the nozzle got any higher than ambient.

on February 15th, 2009 at 9:44 am

Would it be possible to build a folding iteration of your current air sprung HPV? Time for an incremental approach instead of a clean sheet design? There must be some potential to use the suspension pivots as folding points? Unclip the airbags and fold the suspension arms back 180°?

on February 15th, 2009 at 9:58 am

Ford Man, it still ends up too wide and long, even if folded as described. But in terms of taking an incremental approach, the design I am currently working on does take some parts of its apporoach directly from the previous Air 150 design.

on March 3rd, 2009 at 9:30 am

In terms of the front wheel drive, have you considered the moving (i.e. turning with the steering) bottom bracket design? It takes a bit of getting used to on the road, but has the benefit of driveline simplicity, and can contribute to folding just by tuning the bars to brink the pedals back against the frame.. See the cruzbike website for their complete bikes & conversion kits etc. I have recently fitted a conversion kit to an old F-frame Moulton (1960s 16″ wheel rubber suspended bike, in case its unfamiliar to you) and found it quite successful, if rather heavy due to the donor bike. It is an extremely comfortable, low CofG machine, with plenty of storage on the large rear rack. The handling is ‘interesting’ but I am acclimatising to it. I think the moving bottom bracket is well worth a look.

Regards

Huw

PS Keep up the good work at Autospeed— the most interesting car related site I have encountered

on March 3rd, 2009 at 9:40 am

Ian Sims of Greenspeed – an HPV designer for whom I have enormous respect – said to me that it was vital to keep the pedal assembly and the steering completely separate. I could see why, too.