New DIY Electric Car Opportunities

People who have been into modified cars here in Australia have for decades known of the incredible bargains that can be had from Japanese-importing wreckers.

Because of the speed with which Japanese drivers discard near-new cars, the drivelines – or even complete front halves of cars – can be bought amazingly cheaply. Engines and gearboxes boasting late model technology, for less than the cost of having an old clunker rebuilt. It’s simple – buy a locally-delivered car and then install a new Japanese-import driveline having much greater performance. Over the years I’ve done this twice – and both times got a tremendous car for the money.

And now there’s a whole new and exciting Japanese-import field opening up.

Because Japanese manufacturers have led the world in the creation of hybrid petrol/electric cars – the first was built over 10 years ago – and because many were sold locally in Japan, hybrid car parts can now be sourced out of Japan at the same ridiculously low prices.

- » Continue reading or Comments (16)

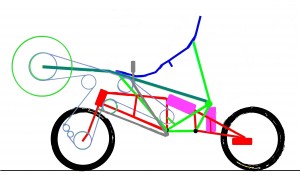

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.

Julian Edgar, 50, has been writing about car modification and automotive technology for nearly 25 years. He has owned cars with two, three, four, five, six and eight cylinders; single turbo, twin turbo, supercharged, diesel and hybrid electric drivelines. He lists his transport interests as turbocharging, aerodynamics, suspension design and human-powered vehicles.